Diamond saw blades are widely used in our daily lives, so how can we judge the quality of diamond saw blades? Here are several common methods

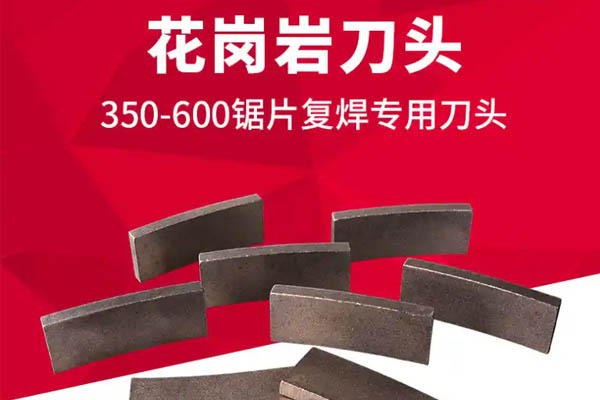

1、 Check if the weld seam is tightly welded to the substrate

After brazing, there will be a weld seam between the weld and the substrate. If the arc-shaped surface at the bottom of the cutting head is completely fused with the substrate, there will be no gap. If there is a gap, it indicates that the cutting head on the diamond saw blade is not completely fused with the substrate, mainly because the arc-shaped surface at the bottom of the cutting head is unevenly polished.

2、 Measure the weight of the saw blade

The heavier and thicker the diamond saw blade, the better, because the heavier the saw blade, the greater the inertial force during cutting, and the smoother the cutting. Generally speaking, a 350mm diamond saw blade should weigh around 2 kilograms, while a 400mm diamond saw blade should weigh around 3 kilograms.

3、 Check if the cutting heads on the diamond saw blade are on the same straight line

If the cutting heads are not on the same straight line, it means that the size of the cutting heads is irregular, some may be wide and some may be narrow, which can cause unstable cutting when cutting stone and affect the quality of the saw blade.

4、 Check the hardness of the substrate

The higher the hardness of the substrate, the less likely it is to deform. Therefore, whether it meets the standard during welding or cutting, the hardness of the substrate directly affects the quality of the saw blade. High temperature welding does not deform, and it does not deform under force majeure conditions, making it a good substrate. After processing into a saw blade, it becomes even better.